FE A

Replacement elements for double changeover DF 4.222 (DN 25/40/50) and DF 4.212 (DN 25)

FE B

Replacement filter elements for single filter EF 4.121 (DN 20/32/50/80), double filter DF 4.225 (DN 20) and DF 4.221 (DN 32/50/80)

FE NSF

Replacement filter elements for By-pass filters NSF 4.125 (vertical and horizontal versions)

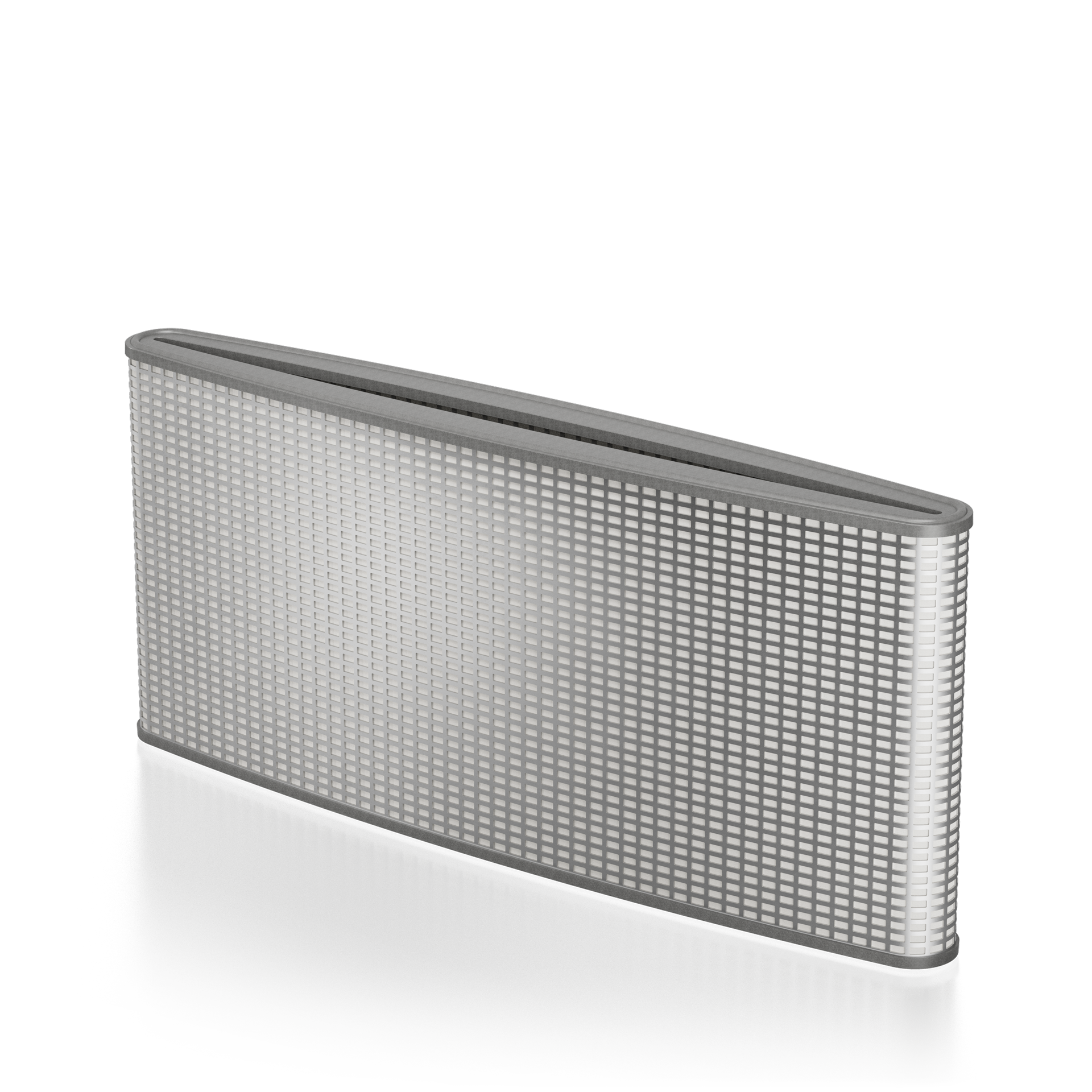

FE DEMISTER

Replacement filterelements for fluidtech® Oil Mist Separator (demister)

Are you searching for a unique filter element solution?

Look no further. At FRIEDRICHS FILTERSYSTEME we specialize in developing and manufacturing custom filter elements tailored to your specifications. Whether you require prototypes or small series, we have the expertise to deliver precisely what you need. Our unique offering includes crafting filter elements for discontinued makes and accommodating quantities as low as 1.

Why choose us?

- Tailored Expertise: Our team excels in bringing your specific filter element requirements to life.

- Unique Solutions: We pride ourselves on creating filter elements for obsolete makes and new applications alike.

- Low Quantity Support: No order is too small. We cater to quantities as low as 1.

Contact us today to discuss your unique requirements.